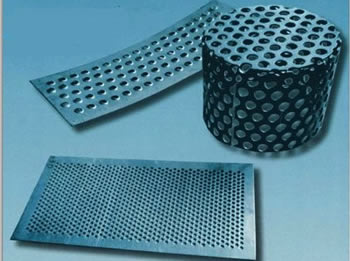

Perforated metals are a type of metal sheet that has been mechanically stamped or punched to create an array of holes, slots or decorative patterns. The process of creating perforated metals involves a mechanical press, which punches the holes or slots into the sheet. The size, shape, and spacing of the holes can be customized to meet specific needs and applications. Read More…

Accurate Perforating is a one-stop shop for complete perforated metal solutions. We can perforate, fabricate and finish almost any metal for almost any use. Whether you need perforated aluminum, carbon steel, galvanized, stainless steel, or copper; in perforated sheets, coils, parts or finished components; or architectural metal, decorative metal, railings, facades or sunscreens — with the...

At Ametco Manufacturing Corporation, we specialize in custom manufacturing a wide range of quality products, including perforated metals, and plastics. Our expertise extends to crafting, perforated sheet, perforated tubes, and perforated metal filter screens. As specialists in metal perforation, we adhere to the strictest guidelines to ensure that every product we deliver meets the highest...

Here at Remaly Manufacturing Company, Inc. we aim to exceed your expectations. Our teams utilize the most efficient manufacturing processes and we strive to provide you with the highest quality solutions. All of our products are pre-tested and we work with you to determine the best perforated metals for your applications.

Here at VACCO Industries, we can create custom perforated metal products, and our engineers will abide to your exact requests. These top of the line products are affordable, and we work hard to make all of our products with precision techniques

More Perforated Metal Manufacturers

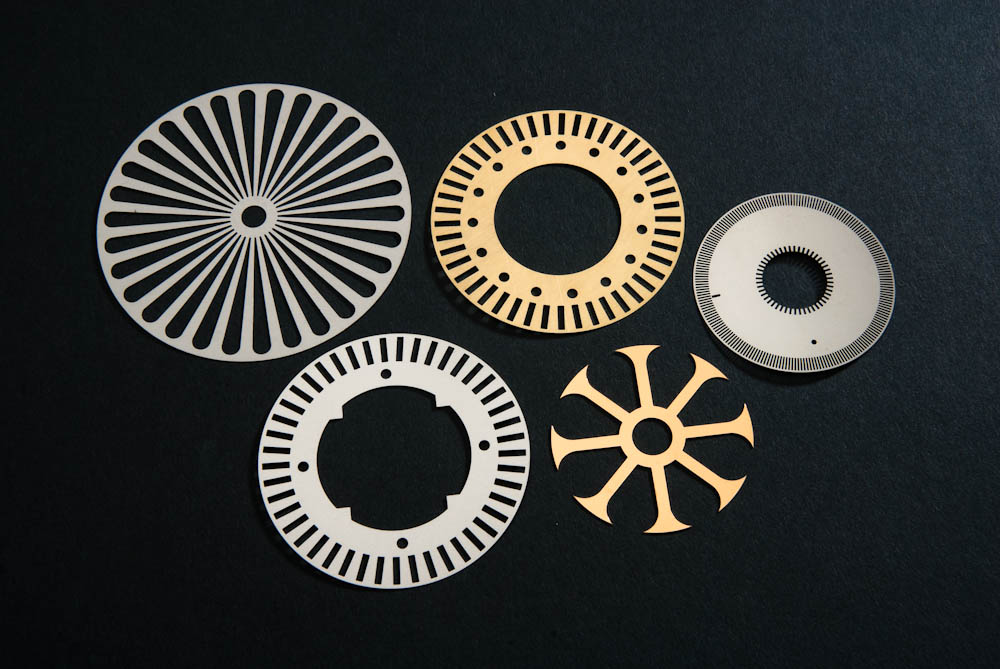

Perforated metals are precision-engineered metal sheets that have been mechanically stamped, punched, or laser-cut to create a highly controlled array of holes, slots, or decorative patterns. The process of producing perforated metals utilizes specialized machinery, such as mechanical presses, CNC punch presses, or fiber laser cutters, to ensure consistency, accuracy, and repeatability for every sheet. The size, shape, and spacing of the perforations can be fully customized, offering exceptional flexibility to meet specific requirements across countless industrial, architectural, and commercial applications.

With a history extending back to ancient civilizations—where metalworkers used primitive hand tools to punch decorative patterns into armor, screens, and ornamental objects—the perforation process truly revolutionized during the Industrial Revolution. The advent of mass production and more advanced metalworking equipment enabled manufacturers to produce perforated metal sheets at scale, transforming their role from purely decorative to highly functional. Today, perforated metals have become an integral material in industries ranging from construction and architecture to filtration, automotive, electronics, energy, and beyond.

Creation of Perforated Metals: Manufacturing Techniques and Precision Engineering

Perforated metal sheets are produced using a variety of advanced manufacturing techniques that ensure both high precision and adaptability. The most common processes include:

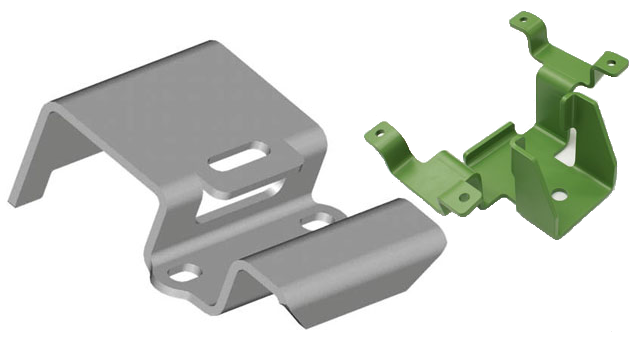

- Punching/Stamping: High-speed mechanical or hydraulic presses equipped with specialized tooling punch holes or slots into the metal sheet. This method is ideal for high-volume production and repetitive patterns, making it a staple in metal fabrication shops.

- Laser Cutting: Fiber or CO2 lasers allow for intricate, non-standard, or custom-shaped perforations with exceptional edge quality and minimal material distortion. Laser cutting is favored for architectural metals and precision components.

- CNC Machining: Computer Numerical Control (CNC) systems automate the perforation process, enabling the creation of highly complex and repeatable patterns across large batches. This technology is essential for applications requiring tight tolerances and design flexibility.

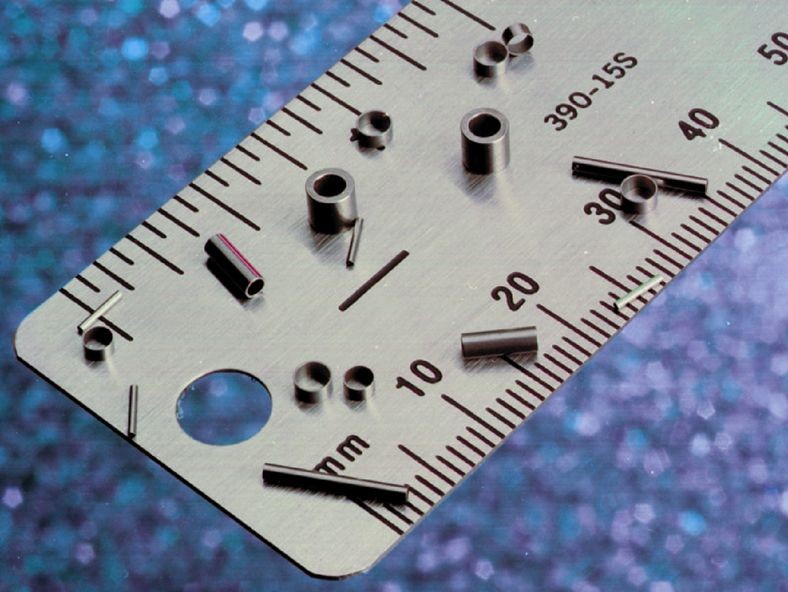

- Rotary Pin Perforation: Used primarily for very thin metals and continuous processing, rotary pin perforation creates fine holes at high speeds, ideal for filtration and screen applications.

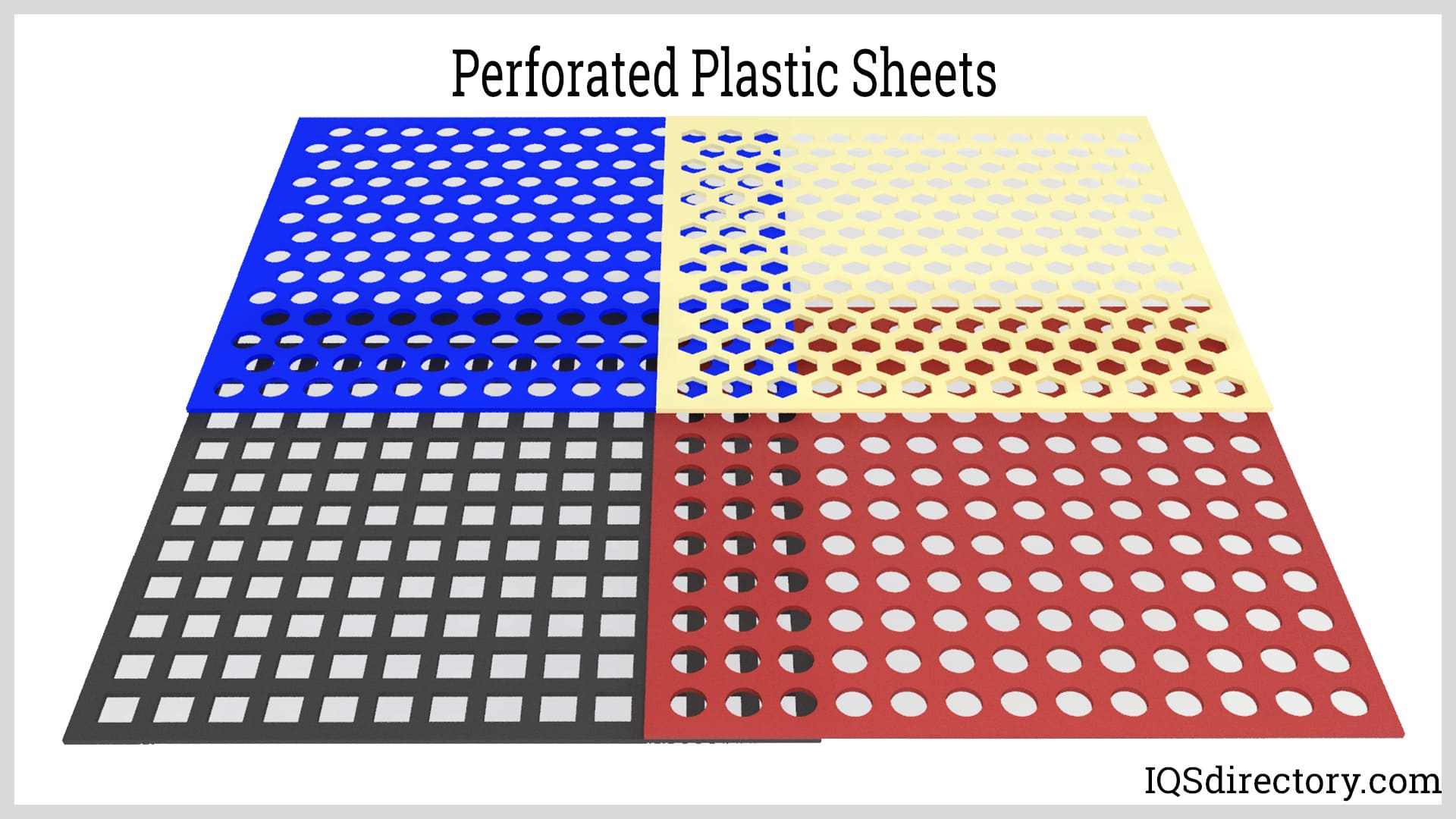

Manufacturers often work with materials such as stainless steel, aluminum, carbon steel, galvanized steel, brass, and copper. With options for round, square, rectangular, slotted, hexagonal, and custom decorative patterns, perforated metal sheets can be engineered to meet any project’s functional or aesthetic needs. The meticulous selection of hole size, open area, and sheet thickness ensures optimal performance for applications such as sound attenuation, screening, separation, or airflow management.

Want to learn more about the specific manufacturing technologies and standards used in perforated metal fabrication? Explore our in-depth guide to perforated metal manufacturing processes.

Types of Metals Used and Key Applications

Perforated metals derive their remarkable versatility from a broad spectrum of base materials, each chosen for its unique mechanical, chemical, and visual properties. Understanding these differences is crucial for selecting the right perforated sheet for your project:

- Stainless Steel: Renowned for its corrosion resistance, tensile strength, and clean modern appearance, stainless steel perforated sheets are the top choice for architectural facades, food processing equipment, medical facilities, and chemical handling systems. Grades such as 304 and 316 stainless steel offer enhanced resistance against harsh environments or marine applications.

- Aluminum: Lightweight, highly malleable, and naturally resistant to oxidation, aluminum perforated panels excel in aerospace, automotive, HVAC, and lightweight architectural designs. Their high strength-to-weight ratio and ease of fabrication make them popular in ventilation grilles and sunshades.

- Carbon Steel: Offering superior durability and cost-effectiveness, carbon steel is frequently used in industrial filtration, machinery guards, mining screens, and agricultural equipment. Options for painting or powder coating further enhance its corrosion resistance for outdoor use.

- Galvanized Steel: By applying a protective zinc coating, galvanized steel perforated sheets combine structural strength with outstanding weather resistance. They are widely used in fencing, guardrails, exterior cladding, and rural infrastructure.

- Copper: With superior electrical and thermal conductivity, copper perforated metal is sought after for electrical components, electromagnetic interference (EMI) shielding, and high-end architectural accents.

- Brass: Combining the malleability of copper with zinc for increased strength and corrosion resistance, brass perforated sheets bring a warm, decorative finish to interior design, signage, and plumbing applications.

Choosing the right metal—considering factors such as corrosion resistance, mechanical strength, thermal conductivity, and aesthetics—directly impacts the performance and longevity of your perforated metal solution.

Still unsure which material is best for your project? Compare the properties and typical applications of each perforated metal type in our material selection guide.

Surface Finishes and Treatments for Enhanced Performance

Surface finishes and treatments play a critical role in extending the lifespan, improving the functionality, and elevating the visual appeal of perforated metals. These treatments are applied to perforated metal sheets to meet specific requirements for any application:

- Powder Coating: This process electrostatically applies a dry powder to the metal, which is then cured under heat to form a tough, uniform, decorative layer. Powder coating is available in a wide range of colors and textures, providing superior UV, abrasion, and corrosion protection for both interior and exterior applications.

- Anodizing: Exclusive to aluminum, anodizing creates a dense oxide layer that enhances corrosion resistance, wear properties, and color stability. Anodized aluminum sheets are common in architectural panels, lighting fixtures, and consumer electronics.

- Galvanizing: By immersing steel in molten zinc, galvanizing delivers long-term rust protection, especially for perforated metal used outdoors or in high-humidity environments.

- Decorative Plating: For high-end or specialty applications, metals like nickel, chrome, or brass can be electroplated onto perforated sheets, offering unique finishes, enhanced conductivity, or antimicrobial properties.

- Custom Finishes: Additional techniques such as brushing, polishing, or applying antimicrobial or anti-graffiti coatings can be specified for specialized uses.

Properly selected surface treatments not only boost resistance to corrosion, abrasion, and environmental exposure but also allow for creative expression in design-driven projects. For example, architects may specify a matte black powder coat for a modern building façade, while food processing engineers may require electropolished stainless steel for sanitary applications.

Curious about which finish is right for your project? Review our chart of surface treatments for perforated metal, including pros and cons for each application.

Limitations of Perforated Metals and How to Overcome Them

While perforated metals offer unparalleled versatility, they do present certain engineering and design challenges:

- Reduced Load-Bearing Capacity: Perforations inherently decrease the structural integrity of the metal sheet. This may limit their use in applications requiring high strength or impact resistance.

- Bending and Deformation: Excessively large holes or high open area percentages can cause the metal to deform or warp during handling or installation.

- Edge Fraying or Burrs: Poorly maintained tooling can create sharp edges, burrs, or inconsistencies in the perforated pattern, affecting both safety and performance.

To address these limitations, manufacturers may:

- Use thicker gauge metal to compensate for lost strength.

- Design reinforcement features such as ribs, flanges, or frames.

- Optimize perforation patterns for even stress distribution across the sheet.

- Specify finishing processes like deburring or edge rolling for safety and aesthetics.

For high-load or safety-critical applications, consulting with an experienced perforated metal supplier is essential to ensure compliance with industry standards and safety codes. Have a complex engineering challenge? Submit your project requirements to our technical team for a custom solution.

Benefits of Perforated Metals: Why Choose Perforation?

Perforated metals deliver an impressive range of advantages, making them a top choice for engineers, architects, OEMs, and designers:

- Superior Airflow and Ventilation: The open area created by perforations allows for controlled airflow, crucial for HVAC systems, air diffusers, electronic enclosures, speaker grilles, and industrial drying processes.

- Lightweight Strength: By removing excess material without compromising overall integrity, perforated metals offer an outstanding strength-to-weight ratio, ideal for automotive and aerospace components.

- Filtration and Separation: Used as screens, sieves, and filters, perforated metal sheets regulate the passage of liquids, gases, or solids—supporting critical processes in oil and gas, food processing, pharmaceuticals, and water treatment.

- Architectural Flexibility: Perforated metal panels are a designer’s dream, offering endless patterns, textures, and finishes for building façades, sunshades, privacy screens, railings, and interior accents.

- Acoustic Management: When used in sound barriers, acoustic panels, or noise control enclosures, perforated metals absorb and diffuse sound, reducing noise pollution in offices, factories, and public spaces.

- Security and Visibility: Durable, tamper-resistant, and offering clear lines of sight, perforated metal is ideal for security screens, machine guards, and protective enclosures.

- Ease of Fabrication and Installation: Perforated sheets can be easily cut, bent, welded, or formed to meet project-specific requirements, streamlining both manufacturing and installation processes.

- Cost Efficiency: The efficient use of material and adaptability to high-volume production make perforated metals a cost-effective solution for many industrial and commercial needs.

Want to see how perforated metal can enhance your next project? Explore our case studies showcasing real-world applications and performance benefits.

Sustainability and Environmental Impact: Green Building with Perforated Metal

Eco-friendly construction and sustainable manufacturing practices are increasingly important in today’s world. Perforated metals stand out for their strong environmental credentials:

- Recyclability: Most perforated metal products are made from materials like stainless steel, aluminum, and copper, all of which can be fully recycled at the end of their service life—reducing raw material consumption and landfill waste.

- Resource Efficiency: The perforation process generates minimal scrap, and offcuts or punch-outs are often recycled directly back into the production process.

- Energy Savings: When incorporated into perforated metal panels for building façades, sunshades, or ventilated screens, these materials help regulate solar heat gain, reduce reliance on air conditioning, and promote natural daylighting—contributing to lower energy use and LEED credits.

- Ventilation and Daylighting: The ability to increase natural airflow and light penetration allows architects to design healthier, more energy-efficient environments.

By choosing perforated metal solutions, building owners and specifiers can meet demanding green building standards, such as LEED, BREEAM, or WELL, while supporting a circular economy model.

Looking for ways to enhance your project’s sustainability rating? Discover our eco-friendly perforated metal options and recycled content certifications.

Customization and Design Possibilities: Unleashing Creativity

Few materials offer the design freedom of perforated metal. With modern CAD/CAM technology, fabricators can create virtually any pattern, motif, or branding element—limited only by imagination:

- Custom Hole Patterns: From standard round or square holes to intricate geometric, floral, or logo-based designs, perforated sheets can be tailored to any aesthetic or functional requirement.

- Variable Open Area: By adjusting hole size, shape, and spacing, designers can control airflow, light diffusion, privacy, or acoustic performance to exact specifications.

- Complex Forming and Assembly: Perforated metal can be bent, curved, rolled, or assembled into complex three-dimensional shapes, enabling striking architectural features or compact mechanical assemblies.

- Integrated Branding: Companies can incorporate logos, signage, or artistic elements directly into the sheet, enhancing brand visibility in both interior and exterior spaces.

- Lighting Effects: The interplay of light and shadow through custom perforations creates dynamic visual effects for ceilings, facades, and public installations.

Whether you’re designing a signature building, a high-tech workspace, or a unique art installation, perforated metal provides unmatched versatility. Need inspiration? Browse our perforated metal design gallery for innovative ideas and real-world examples.

How to Choose the Correct Perforated Metal: A Step-by-Step Guide

Selecting the optimal perforated metal for your application involves several key decision points:

- Define Your Application: Is your project focused on ventilation, filtration, structural support, acoustic management, or visual design? Each use case dictates different performance requirements.

- Choose the Right Material: Consider environmental exposure (e.g., moisture, chemicals, UV), mechanical demands (load-bearing or impact), and desired aesthetics. Stainless steel offers unmatched durability; aluminum is best for lightweight needs; galvanized steel excels outdoors, while copper or brass adds decorative flair.

- Select Perforation Pattern and Open Area: Determine the ideal hole shape, size, spacing, and overall open area percentage to balance strength, airflow, privacy, and appearance.

- Specify Sheet Thickness and Dimensions: Choose a thickness that supports your structural and fabrication requirements, and don’t forget to confirm maximum sheet size for your installation space.

- Decide on Surface Finish or Treatment: Will your metal require powder coating, anodizing, or special plating for corrosion resistance or visual impact?

- Consult with Experts: Partner with a reputable perforated metal manufacturer or supplier to validate your design choices and ensure compliance with project standards or industry codes.

For complex or mission-critical applications, requesting sample sheets or prototypes is highly recommended to confirm fit, finish, and performance.

Need help specifying your perforated metal? Contact our technical support team for expert guidance or request a custom quote today.

Applications of Perforated Metals Across Industries

Perforated metals are truly multi-purpose. Here’s how they’re used across major sectors:

- Architecture & Construction: Building façades, sunscreens, privacy screens, stair treads, balustrades, and interior partitions leverage perforated metal for both function and striking aesthetics.

- Industrial Manufacturing: Filtration screens, separation sieves, drying trays, noise control barriers, safety guards, and ventilation panels are all made with perforated sheet metal.

- Automotive & Transportation: Grilles, engine covers, heat shields, and ventilation components benefit from the lightweight strength and airflow control of perforated aluminum or steel.

- Food & Beverage Processing: Baking trays, sieves, drainage screens, and sorting machines utilize stainless steel perforated plates for hygiene and durability.

- Electronics & Energy: RFI/EMI shielding, battery enclosures, light diffusers, and solar panel frames use perforated copper, aluminum, or specialty alloys.

- Public Infrastructure: Acoustic barriers along highways, security fencing, trash receptacles, and street furniture all incorporate perforated metal for safety, aesthetics, and durability.

Stainless steel, aluminum, copper, brass, and carbon steel are among the most commonly perforated metal types. Each offers unique properties that optimize performance in their respective applications:

Stainless Steel: Stainless steel is favored for perforated metals due to its exceptional resistance to corrosion, high durability, and ability to maintain its shape and strength even in the harshest environments. You’ll find stainless steel perforated sheets in food processing plants, chemical factories, medical facilities, and as sophisticated architectural accents.

Aluminum: Lightweight, non-magnetic, and easy to form, aluminum perforated sheets are perfect for applications where weight reduction is critical, such as in aerospace, automotive, and large-scale architectural features. Its inherent corrosion resistance also makes it ideal for exterior installations and marine environments.

Copper: Copper’s excellent electrical and thermal conductivity makes it a preferred material for electronic enclosures, EMI/RFI shielding, and heat exchangers. Its natural patina and warm tone are also prized in decorative building elements and artistic installations.

Brass: With its classical golden hue, brass offers both durability and corrosion resistance. It is often used in decorative screens, signage, plumbing fixtures, and electrical connectors where appearance and longevity are equally important.

Carbon Steel: High strength and cost-effectiveness make carbon steel the choice for heavy-duty industrial applications—such as mining screens, machinery guards, and agricultural equipment—as well as for structural supports in building construction.

Want to match your application with the optimal perforated metal type? Use our interactive material selection tool or download our perforated metal application guide.

The Future of Perforated Metal: Trends and Innovations

The world of perforated metals is rapidly evolving as manufacturers embrace cutting-edge technologies and shifting market demands. Key trends shaping the future include:

- Advanced Manufacturing: The integration of 3D printing and additive manufacturing is unlocking new levels of design complexity, enabling the creation of multi-layered, gradient, or variable-density perforated structures previously impossible with traditional methods.

- Smart Materials: Research into nano-coatings, self-healing surfaces, and hybrid metal composites will further enhance corrosion resistance, reduce maintenance, and extend product lifespans.

- Digital Customization: Modern CAD/CAM platforms allow designers and engineers to rapidly prototype and iterate unique patterns, facilitating the rise of bespoke architectural features and branded installations.

- Sustainability: The demand for recycled, eco-friendly metals and energy-efficient manufacturing processes is driving innovation toward greener, more responsible production.

- New Applications: As industries push for lighter, stronger, and more efficient materials, perforated metal is finding new uses in renewable energy, electric vehicles, smart cities, and advanced electronics.

Are you ready to leverage the latest innovations in perforated metal? Stay ahead with our industry insights and technology updates newsletter.

How to Choose the Proper Perforated Metal Manufacturer

Ensuring a successful perforated metal project begins with selecting the right manufacturer or supplier. Here’s how our directory streamlines your sourcing process:

- Comprehensive Company Profiles: Each perforated metal manufacturer in our directory provides in-depth business profiles detailing their technical capabilities, materials expertise, and value-added services (such as design consultation, prototyping, and finishing).

- Quick Specialization Search: Use our patented website previewer to instantly evaluate each company’s areas of specialization—saving you time and helping you focus on the best matches for your industry or project type.

- Easy RFQ Process: Contact manufacturers directly using our streamlined Request for Quote (RFQ) form. Submit your specifications once and receive competitive quotes from multiple vetted suppliers.

- Expert Consultation: Many companies offer technical support, material selection guidance, and even design assistance to ensure your perforated metal solution meets all functional, aesthetic, and regulatory requirements.

Ready to start your project? Browse our list of perforated metal manufacturers, compare capabilities, and request your custom quote today.

Still have questions? What is the best perforated metal for outdoor use? How do I specify a custom hole pattern for my project? What standards or certifications are important for my industry? Our experts are here to help—contact us for guidance or tailored recommendations.

Check out our Wire Mesh website

Check out our Metal Stampings website

What are perforated metals and how are they manufactured?

Perforated metals are metal sheets that have been mechanically stamped, punched, or laser-cut to produce a controlled array of holes, slots, or patterns. Manufacturing techniques include punching/stamping with mechanical or hydraulic presses, laser cutting, CNC machining, and rotary pin perforation. These methods allow for exceptional precision, customization, and consistency across various metals and applications.

Which metals are commonly used for perforated metal sheets?

Commonly used metals for perforated sheets include stainless steel, aluminum, carbon steel, galvanized steel, copper, and brass. Each offers unique mechanical, chemical, and visual qualities for a wide range of industrial, architectural, and commercial applications.

What surface finishes and treatments are available for perforated metals?

Surface finishes and treatments for perforated metals include powder coating, anodizing (for aluminum), galvanizing (for steel), decorative plating, and custom options like brushing or polishing. These finishes enhance corrosion resistance, aesthetics, wear properties, and sometimes specific functional qualities like antimicrobial protection.

What are the main benefits of using perforated metals?

Perforated metals offer superior airflow and ventilation, lightweight strength, effective filtration and separation, architectural flexibility, acoustic management, improved security and visibility, ease of fabrication, and cost efficiency. Their versatility makes them ideal for many industries and creative design applications.

What are the limitations of perforated metals and how can they be addressed?

Limitations of perforated metals include reduced load-bearing capacity, risk of bending or deformation, and potential for sharp edges or burrs. Manufacturers overcome these challenges by using thicker gauges, adding reinforcement features, optimizing perforation patterns, and applying finishing processes like deburring for safety and aesthetics.

How do I select the right perforated metal for my application?

Selecting the correct perforated metal involves defining your application, choosing a suitable material, selecting the appropriate hole pattern and open area, determining sheet thickness and dimensions, deciding on a surface finish, and consulting with experts or manufacturers to ensure compliance and optimal performance.

What applications and industries use perforated metals?

Perforated metals are used in architecture and construction (facades, sunscreens), industrial manufacturing (filters, guards), automotive and transportation (grilles, heat shields), food and beverage processing (trays, sieves), electronics and energy (enclosures, shielding), and public infrastructure (acoustic barriers, fencing).

Are perforated metals sustainable and environmentally friendly?

Yes, most perforated metals are fully recyclable and their production generates minimal scrap, often recycling offcuts directly. Perforated metal panels can help regulate solar heat gain, improve energy efficiency, and contribute to green building certifications such as LEED and BREEAM.

Broaching

Broaching CNC Machining

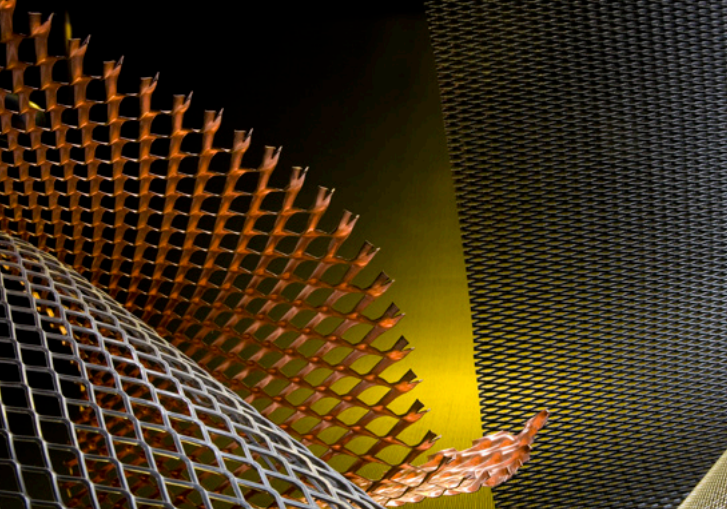

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services