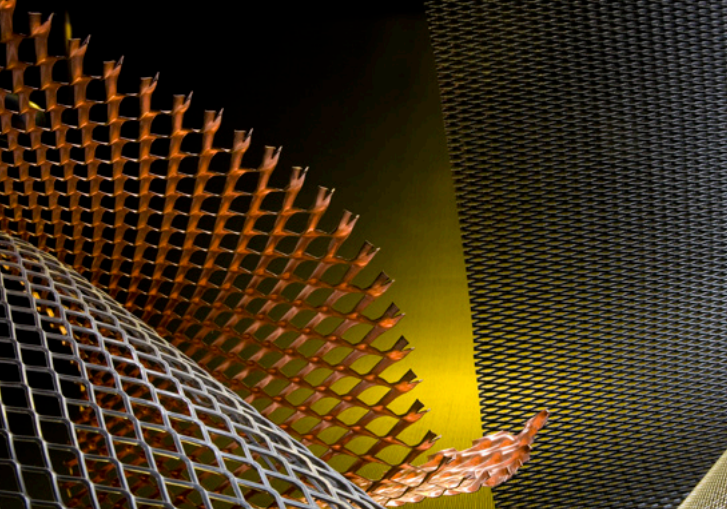

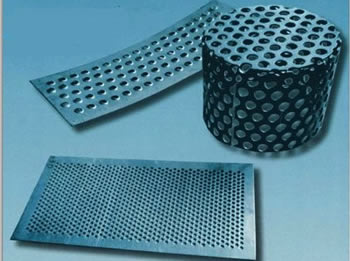

Perforated coils are manufactured by perforating an entire line of a flat rolled sheet. The ends of these can be deformed freely during the rolling and feeding process. Then after the punching process, it will be wounded back into a uniform coil. These coils are made in an industrial perforating press that is called a perforation line and is fed on the machine and perforated continuously. Read More…

Accurate Perforating is a one-stop shop for complete perforated metal solutions. We can perforate, fabricate and finish almost any metal for almost any use. Whether you need perforated aluminum, carbon steel, galvanized, stainless steel, or copper; in perforated sheets, coils, parts or finished components; or architectural metal, decorative metal, railings, facades or sunscreens — with the...

At Ametco Manufacturing Corporation, we specialize in custom manufacturing a wide range of quality products, including perforated metals, and plastics. Our expertise extends to crafting, perforated sheet, perforated tubes, and perforated metal filter screens. As specialists in metal perforation, we adhere to the strictest guidelines to ensure that every product we deliver meets the highest...

Here at Remaly Manufacturing Company, Inc. we aim to exceed your expectations. Our teams utilize the most efficient manufacturing processes and we strive to provide you with the highest quality solutions. All of our products are pre-tested and we work with you to determine the best perforated metals for your applications.

Here at VACCO Industries, we can create custom perforated metal products, and our engineers will abide to your exact requests. These top of the line products are affordable, and we work hard to make all of our products with precision techniques

More Perforated Coil Manufacturers

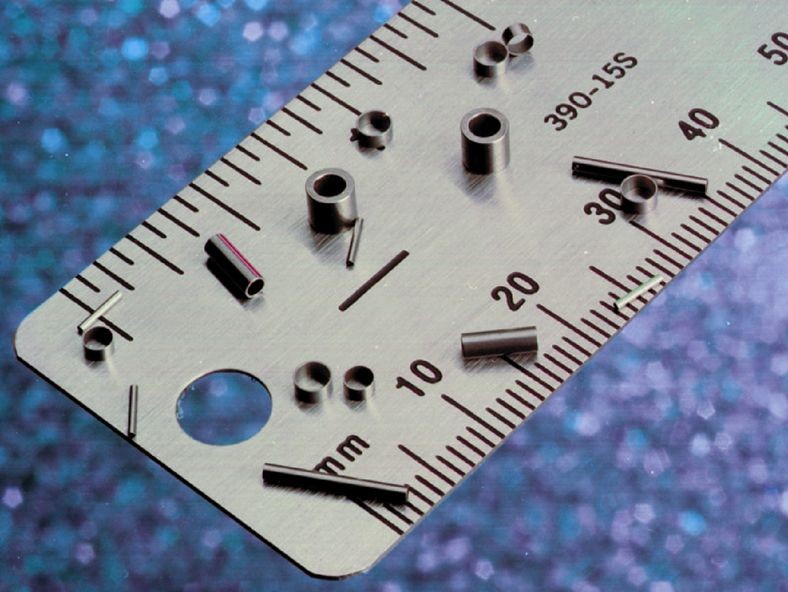

The perforation line consists of components like unwinder with a straightener, punching press, a shear for cutting in length, and a recoiler, that work alongside each other to successfully fabricate a perforated coil. The unwinder with a straightener is responsible for making it easy for feeding the plain coil to the machine’s feed rollers. Moving forward in the process, a punching press will do its job to punch the pre-defined holes thereby perforating the coil. The punching system will then stop when the desired length is achieved and will be cut by the designated shear for cutting the sheets. Depending on the demand of clients and customers, if they desire a whole coil perforated, then these coils will not be cut and will immediately proceed to the rewinding step.

There are advantages of using perforated coils over its sheet counterpart. One impressive benefit coming from the ability to perforate coils instead of just sheets is having this greatly lessen the cost of raw materials because of bulk production. Furthermore, due to its systematic perforation line, it boasts the ability of having a short time for perforation and production. This results in lessened labor and efficient use of resources.

On the other side, these coils also have their own disadvantages. For one, the molds and dies used as tools for perforation are very expensive. Having mentioned this, the possibility to produce customized holes for these types of perforations will be limited only to the available mold and die the manufacturer has. Finally, the capability of the perforation line for coils are only limited to a low and medium thickness materials, that is why sheets are more preferred for thicker applications.

Perforated Coils are used in applications where the production line requires big lots/ high volume of perforated materials that have a low to medium thickness. Because of its ability to produce a whole punched coil, these make it perfect for OEMs (Original Equipment Manufacturers) that have a large and automated production line. Looking on the consumer side, coils have a wide application in the industry in which they are used as partitions, enclosures, sign panels, safety guards, and screens. With its efficient production line, perforating coils boost the production time and cost savings by making the process of handling sheet material lean and effective.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

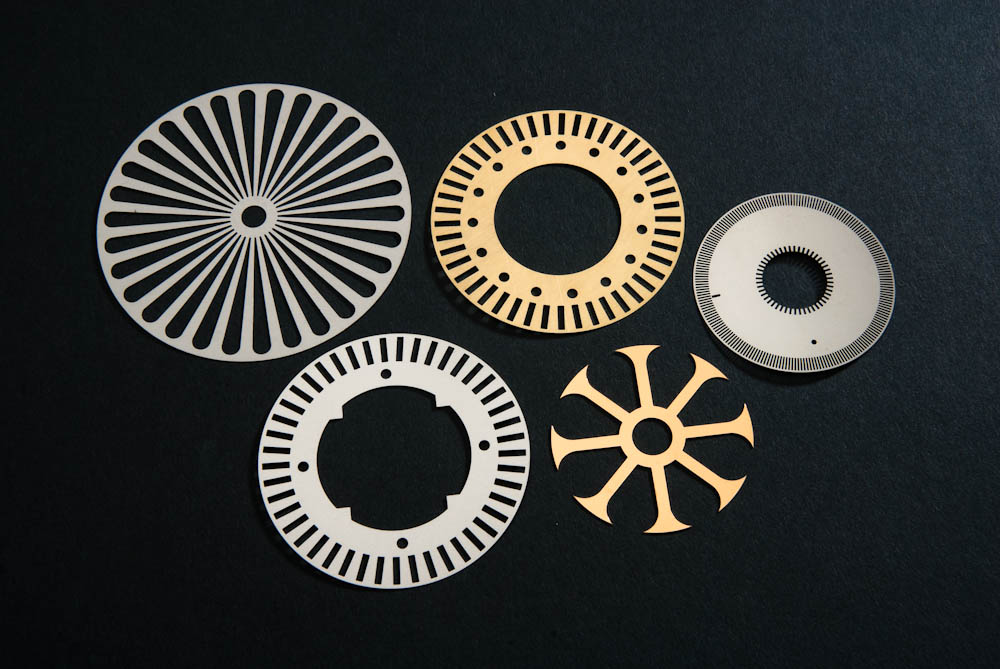

Laser Cutting Metal Etching

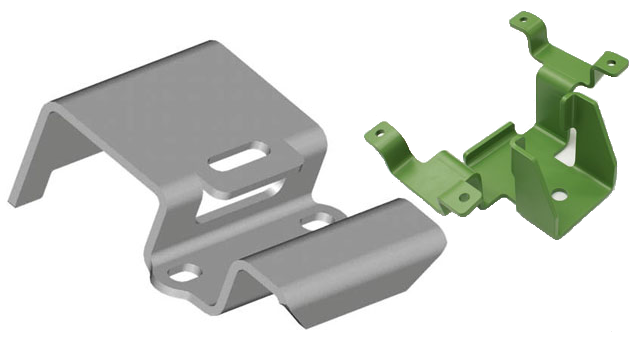

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services