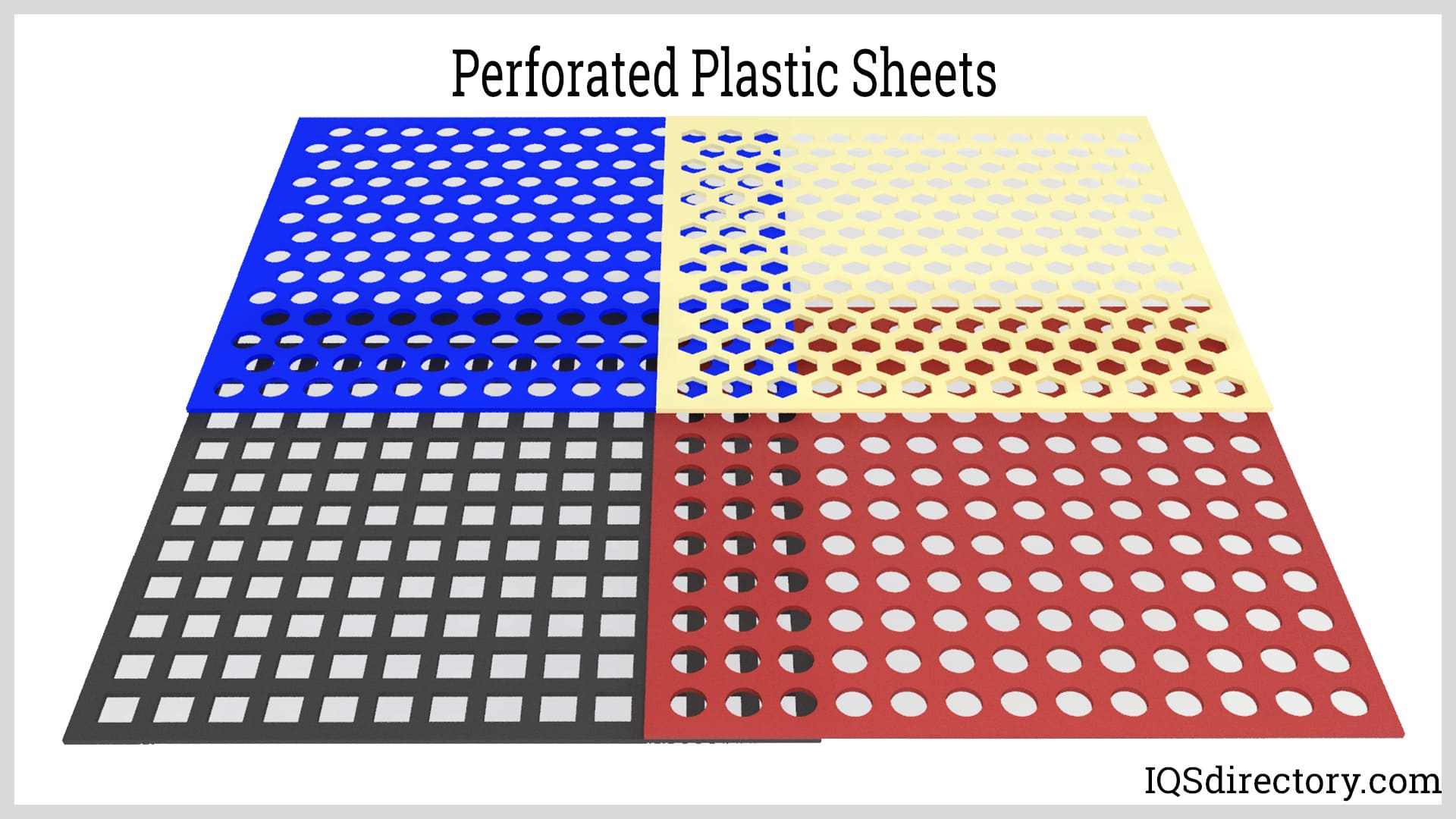

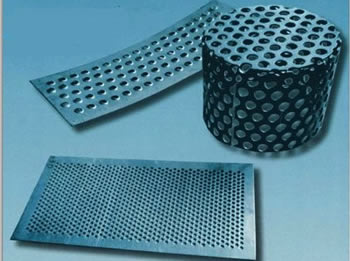

Plastic perforated sheets are made from several types of plastics that are chosen in accordance with the application for which the sheets will be used. The design and manufacture of the majority of perforated plastic sheets are for the control of air streams and airflow since the holes and openings in the sheets can direct air into specific locations in order to maintain even and uniform temperatures. Read More…

At Ametco Manufacturing Corporation, we specialize in custom manufacturing a wide range of quality products, including perforated metals, and plastics. Our expertise extends to crafting, perforated sheet, perforated tubes, and perforated metal filter screens. As specialists in metal perforation, we adhere to the strictest guidelines to ensure that every product we deliver meets the highest...

Accurate Perforating is a one-stop shop for complete perforated metal solutions. We can perforate, fabricate and finish almost any metal for almost any use. Whether you need perforated aluminum, carbon steel, galvanized, stainless steel, or copper; in perforated sheets, coils, parts or finished components; or architectural metal, decorative metal, railings, facades or sunscreens — with the...

Here at Remaly Manufacturing Company, Inc. we aim to exceed your expectations. Our teams utilize the most efficient manufacturing processes and we strive to provide you with the highest quality solutions. All of our products are pre-tested and we work with you to determine the best perforated metals for your applications.

More Perforated Plastic Sheet Manufacturers

Aside from their practical use, perforated plastic sheets are used for the backing of displays, the construction of room dividers, and decorative accent items.

The characteristics and properties of the plastics used to produce provide the strength, durability, stability, and shape that makes perforated plastic sheets so widely used. The types of plastic chosen to produce perforated plastic sheets vary in their density, structure, and toughness with high density plastics capable of performing like metals while less durable low density plastics are selected for less stressful applications.

Types of Plastics Used for Perforated Plastics

Perforated sheets are made from a wide range of materials that determine the strength of the sheets and their use. Although metals are a popular choice, there are certain applications that require materials that are resistant to chemicals, corrosion, and rust. In those circumstances and environments, plastic perforated sheets are the better choice since most forms of plastics are unaffected by certain chemicals, and plastics are not susceptible to rust or corrosion.

Polypropylene

Polypropylene is a low-density form of plastic that is produced from a propene monomer. It is the second most used plastic in the world after the various forms of polyethylene. Polypropylene is a type of thermoplastic that can be shaped, reshaped, and shaped multiple times without losing its tensile strength or suffering deterioration. The lightweight structure and moisture resistance of polypropylene make it ideal for the production of plastic perforated sheets.

The two types of polypropylenes are homopolymers and copolymers, which differ in how they are produced. Homopolymers are manufactured by the polymerization of propylene with a catalyst. They have a high strength-to-weight ratio combined with chemical resistance and weldability, which makes it possible to use polypropylene homopolymers in a wide range of applications. Aside from its chemical resistance and weldability, homopolymers have exceptional resistance to impact and are food-safe for use in the food industry.

Copolymer polypropylene is formed using one or more comonomers with polypropylene. The process makes it possible to adjust the properties of the final plastic and orient it toward a specific application. The different combinations can improve flexibility, resistance to impacts, increase the transparency of the plastic, and change the materials to meet specific parameters. The use of copolymer polypropylene is constantly expanding and includes use in the manufacture of automobiles, packaging, medical instruments, and household goods. The two common types of copolymers are impact copolymers and random copolymers.

Polyvinyl Chloride (PVC)

Polyvinyl chloride is widely used for the manufacture of piping due to its strength and its resistance to chemicals. It is a polymer that is made from the vinyl chloride monomer and is a low cost highly durable plastic. The properties of polyvinyl chloride can be adjusted using additives such as plasticizers, stabilizers, lubricants, fillers, pigments, and various forms of flame retardants. The purpose of the additives is to change the properties of PVC to meet the special needs of an application.

When a low level of plasticizers is used in the production of PVC, the material becomes exceptionally rigid, which makes PVC ideal for the manufacture of perforated plastic sheets. The high rigidity, hardness, and impact resistance created by the adjustment to the plastic radically decreases its inflexibility such that its strength is comparable to that of some metals. Further adjusting the plasticizer level removes some of its rigidity and makes the plastic sheets more pliable.

High-Density Polyethylene (HDPE)

Polyethylene is the most widely used plastic in the world. The different types of polyethylene are used to manufacture wear pads, gears, parts for oil and gas production, storage tanks, and bearings. Of the different grades of polyethylene, high-density polyethylene is the most used due to its high tensile strength. Aside from its exceptional strength, HDPE, as with all forms of plastics, is resistant to corrosion. In addition, it is resistant to the effects of various forms of acids and alkali.

The tensile strength and rigidity of high-density polyethylene is the reason that it is used for the manufacture of perforated plastic sheets. Since HDPE is exceptionally strong, perforated sheets made of HDPE are used in construction projects for the food industry. Aside from its strength, HDPE has excellent impact resistance, is lightweight, and does not absorb moisture. The high strength-to-density ratio of HDPE protects it from breaking when placed under tension, which makes it possible for the plastic to handle heavy materials and a wide range of liquids without exhibiting signs of damage.

Methods Used to Produce Perforated Plastic Sheets

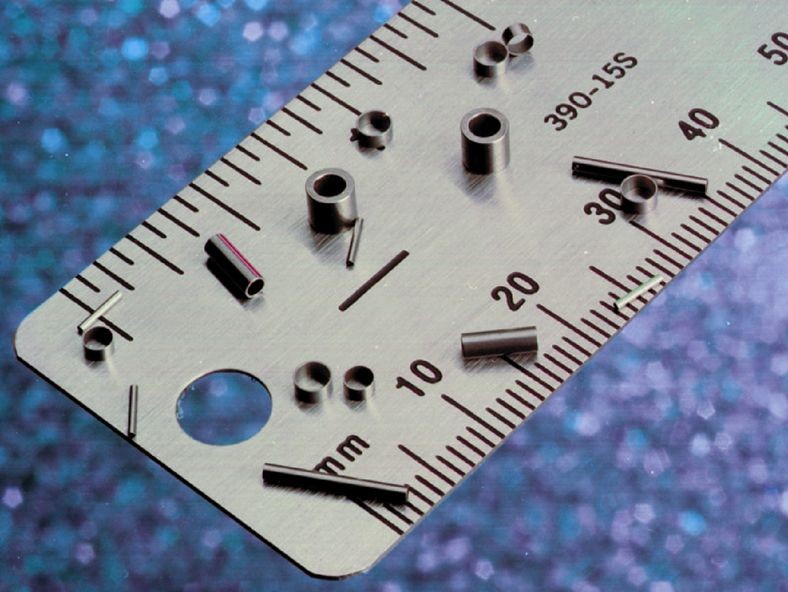

The manufacture of perforated plastic sheets takes several forms, which vary in speed, types of patterns, and the ability to be adjusted for the manufacture of custom perforated sheets. Regardless of the method used to produce perforated plastic sheets, all methods involve placing holes in sheets of different plastics that have varying thicknesses. The variations in the thicknesses of perforated plastic play a part in selecting the type of equipment for punching holes in the plastic since some methods are gentler than others.

Another factor that differentiates the perforation processes is the amount of heat that is used since some methods heat the pins that puncture the plastic. In addition, the feeding methods that are used vary in regard to the form of plastic being processed with some equipment using sheets of plastic while others feed rolls of plastic that are punctured and cut into sheets.

A significant difference between manufacturing methods is the difference between hot and cold placement of hole patterns in plastic sheets. The cold puncturing process uses force to place hole patterns and produces waste material that is collected and removed. The hot method of puncturing plastic sheets cauterizes and melts the plastic sheets, which reduces the amount and form of the waste material. With rotary perforation, the pins that produce the holes are heated. With laser perforation, the pinpoint accuracy of the laser creates the holes and shapes without creating waste.

A common form of perforating is the use of a die punch, which is a less expensive perforating method that requires the collection of plastic waste. In all of the methods that produce waste, including the die punch method, the collected waste is reused for the production of plastic sheets.

Conclusion

The strength, durability, and appearance of perforated sheets are directly related to the plastics that are chosen to produce the sheets. In most cases, the strongest and most resilient plastics are used, with some exceptions being related to how the sheets will be used. Regardless of the type of plastics and the methods of manufacturing, perforated plastic sheets have found wide usage in many applications and have become an important part of several projects and products.

Broaching

Broaching CNC Machining

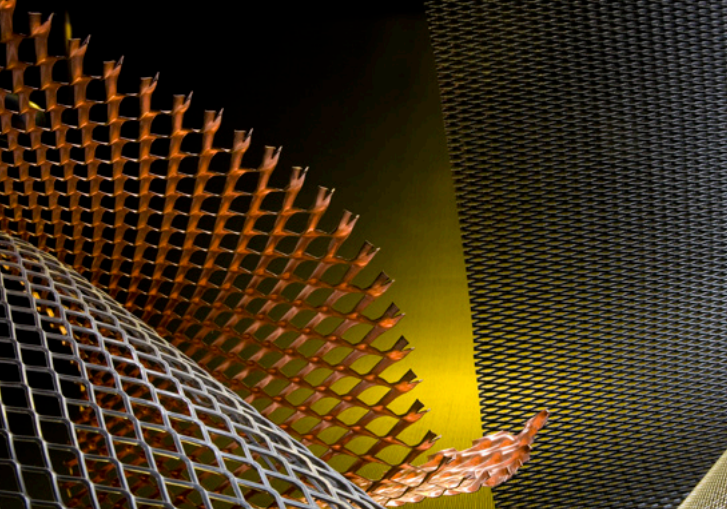

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

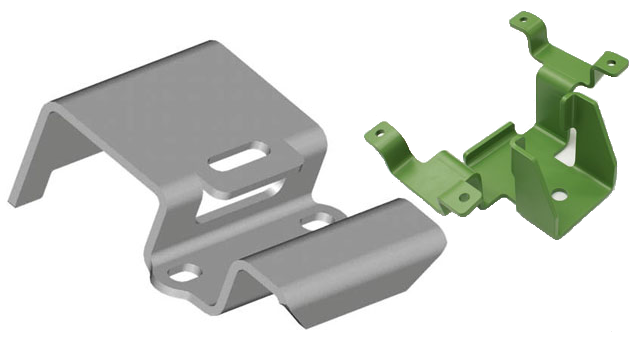

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

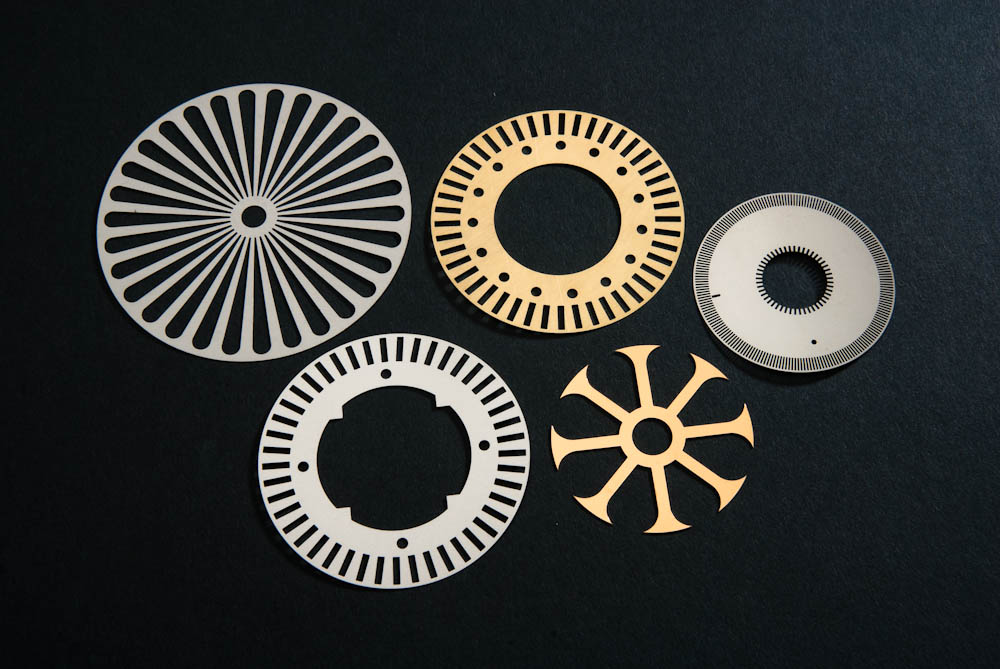

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services