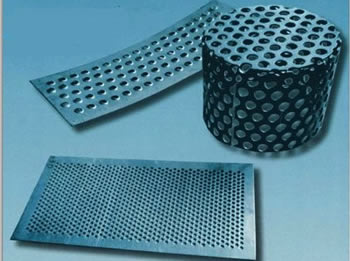

Stainless steel sheets with holes, forms, or patterns punched into them are perforated stainless steel. It is resistant to corrosion, robust, and light. In addition, when steel is alloyed with chromium, a rough, invisible, corrosion-resistant coating is permanently formed on the surface of the steel. This coating makes perforated steel ideal for outdoor applications or exposure to moisture. Stainless steel perforated sheets are used for structural and ornamental applications. Read More…

Accurate Perforating is a one-stop shop for complete perforated metal solutions. We can perforate, fabricate and finish almost any metal for almost any use. Whether you need perforated aluminum, carbon steel, galvanized, stainless steel, or copper; in perforated sheets, coils, parts or finished components; or architectural metal, decorative metal, railings, facades or sunscreens — with the...

At Ametco Manufacturing Corporation, we specialize in custom manufacturing a wide range of quality products, including perforated metals, and plastics. Our expertise extends to crafting, perforated sheet, perforated tubes, and perforated metal filter screens. As specialists in metal perforation, we adhere to the strictest guidelines to ensure that every product we deliver meets the highest...

Here at Remaly Manufacturing Company, Inc. we aim to exceed your expectations. Our teams utilize the most efficient manufacturing processes and we strive to provide you with the highest quality solutions. All of our products are pre-tested and we work with you to determine the best perforated metals for your applications.

Here at VACCO Industries, we can create custom perforated metal products, and our engineers will abide to your exact requests. These top of the line products are affordable, and we work hard to make all of our products with precision techniques

More Perforated Stainless Steel Manufacturers

Manufacturing Process of Perforated Stainless Steel

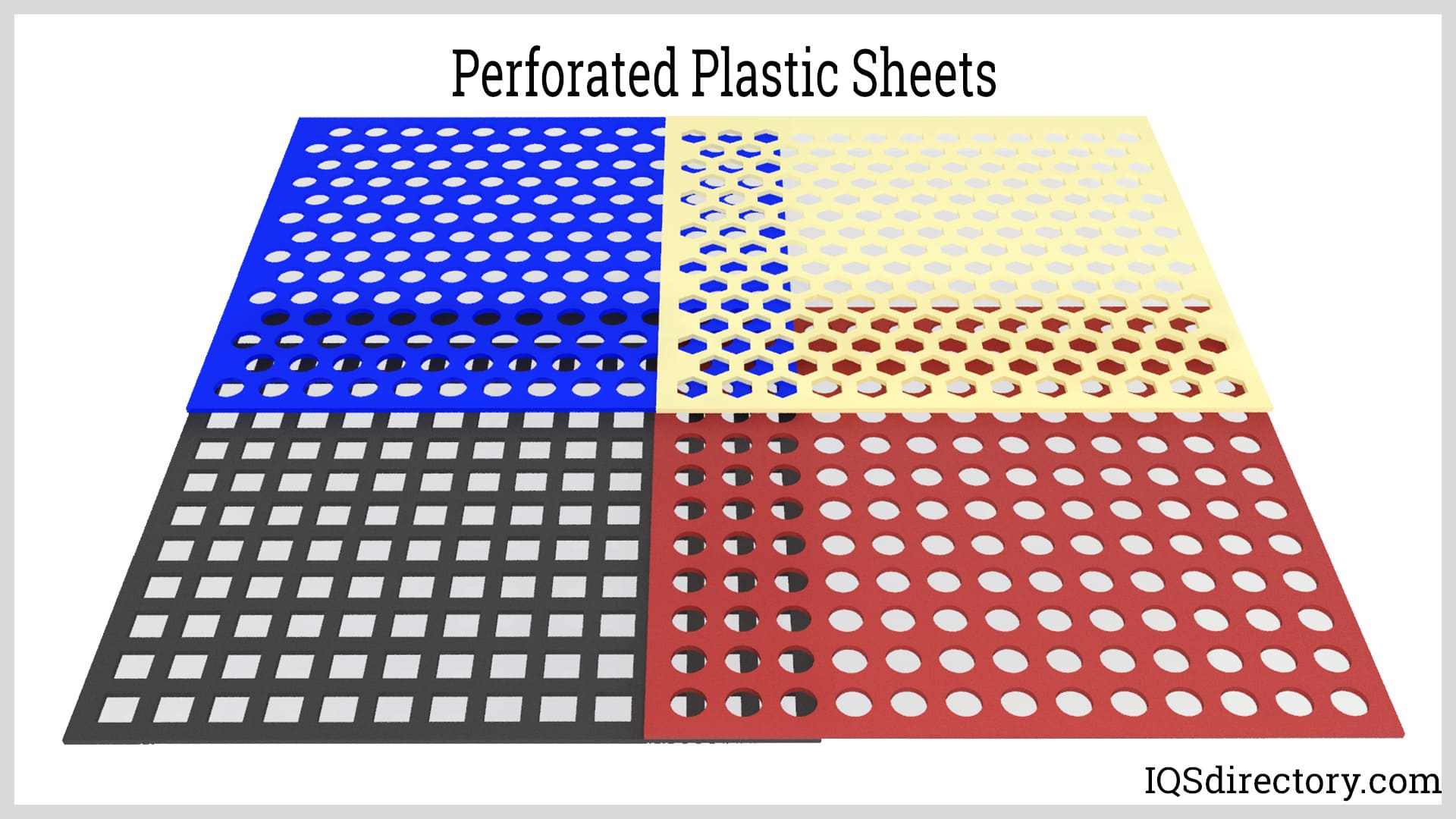

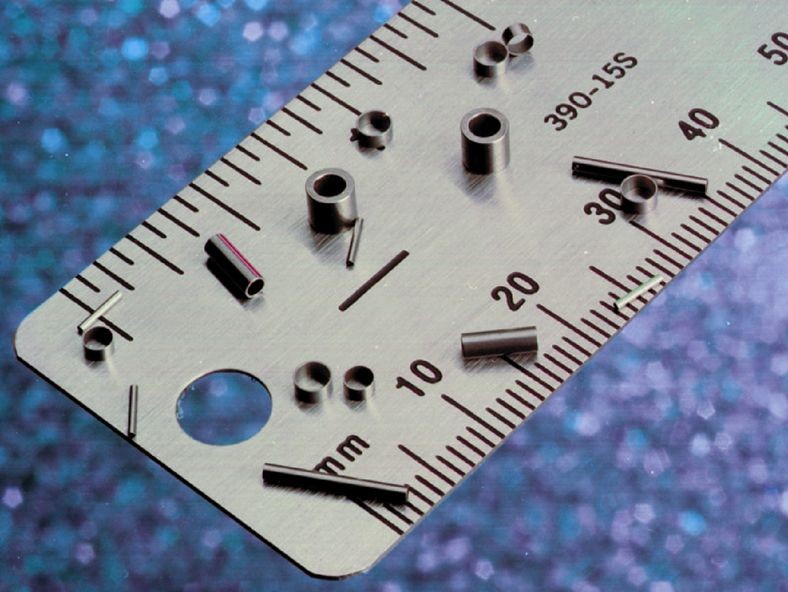

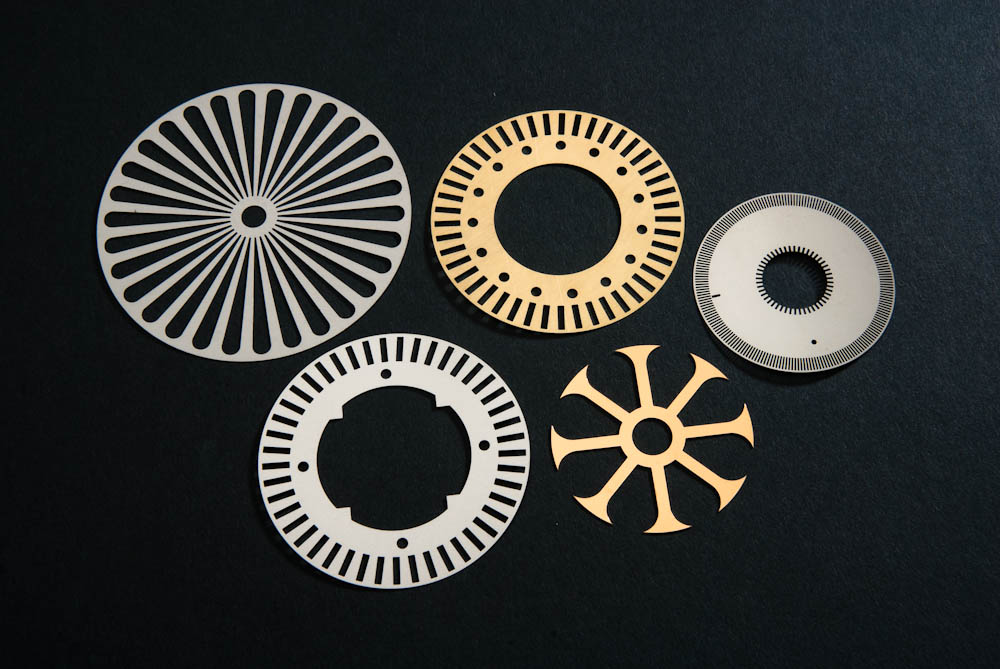

There are 15 different types of stainless steel used in the production of perforated goods, all of which are impervious to the growth of bacteria, rust, and corrosion. Each has several finishes: matte, satin, brushed, reflecting, rough, and abrasive. Round, square, oval, triangular, diamond, hexagonal, slot, star-shaped holes, and other shapes are punched into stainless steel. These forms can create complex and aesthetically pleasing patterns.

Stainless steel sheets are perforated in two ways, depending on the design’s complexity. Both processes start when stainless-steel sheets are fed into the punching press. First, all-cross-perforated punching presses are utilized for straightforward, repeated designs that span the entire sheet. These metal shaping machines' rams puncture the thin sheet of stainless steel to form the required pattern. Next, a sectional two-axis punching press creates custom designs. This CNC-controlled technology slides the sheet below a fixed punching ram.

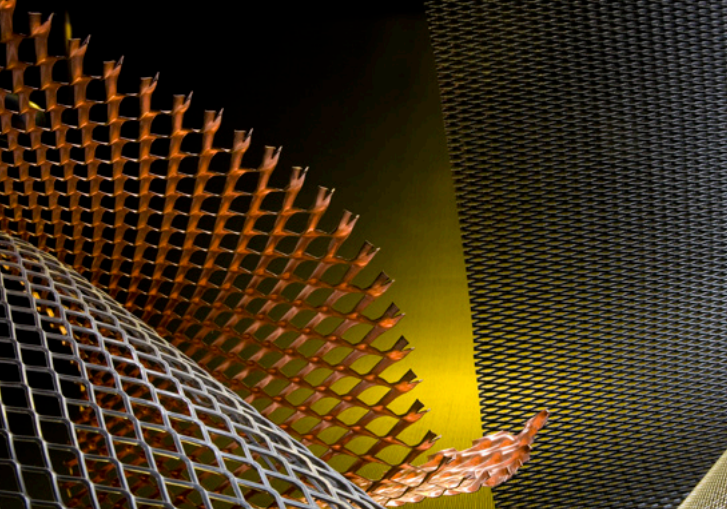

The term "perforated metal," also referred to as "perforated sheets, plates, or screens”, refers to sheet metal that has been manually or mechanically stamped, punched, or pierced using CNC technology or laser cutting. Stainless steel, cold rolled steel, galvanized steel, brass, aluminum, tinplate, copper, Monel, Inconel, titanium, plastic, and other materials are used to make perforated metal sheets.

Metal sheet perforation has been a common practice for more than 150 years. Metal screens were employed to separate coal effectively in the late 19th century. Workers who would physically punch individual holes into the metal sheet were the first perforators. Perforating needed to be more effective and consistent, which prompted the creation of new methods, such as perforating the metal with a succession of needles set to produce the desired pattern of holes.

Utilizing technology and equipment is a part of contemporary perforation techniques. For example, rotary-pinned perforation rollers, die and punch presses, and laser perforations are common pieces of machinery for perforating metal.

Benefits of Perforated Stainless Steel

Perforated metal's acoustic properties assist people or workers in reducing the negative impacts of noise on their health. Perforated metals have been demonstrated in studies to help lower sound levels. Studies have indicated that using perforated metal sheets in front of a building's façade can save energy used for heating, ventilation, and lighting.

Applications of Perforated Stainless Steel

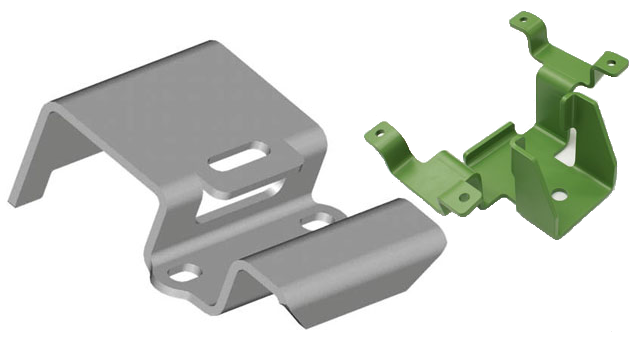

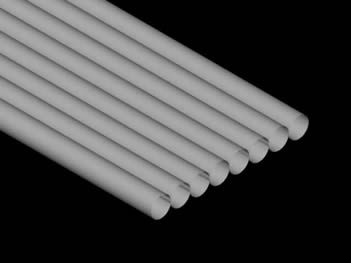

Perforated stainless steel is manufactured in sheets, tubes, pipes, plates, screens, and panels. Stainless steel perforated goods are commonly utilized in exterior building construction as grating, screens, sun shields, lighting diffusers, stair treads, facades, and decorative panels.

Outdoor furniture, including tables, benches, and seats, are made of perforated stainless steel to avoid snow and rain collection on the surface. Stainless steel is easy to clean because of its smooth surface and absence of contaminants. Perforated stainless steel sheets are used as filters and sifters in the beverage, potable water, and pharmaceutical industries. Perforated stainless steel is used in culinary appliances like pans and filters and equipment for clean room workstations.

Numerous industries have used perforated metal. In the architectural sector, buildings have perforated metal as fence screens, infill panels, sunshades, cladding, column coverings, and metal signs. The agricultural sector uses perforated metal in building beehives, drying grains, making wine, raising fish, ventilating silos, sorting equipment, and making juice. Chemical and energy-related equipment uses perforated metal in filters, centrifuges, drying machine baskets, battery separator plates, water screens, gas purifiers, liquid gas burning tubes, and mine cages.

Choosing the Right Perforated Stainless Steel Manufacturer

To ensure you have the most positive outcome when purchasing perforated stainless steel from a perforated stainless steel manufacturer, it is important to compare several companies using our directory of perforated stainless steel manufacturers. Each perforated stainless steel manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each perforated stainless steel business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple perforated stainless steel companies with the same form.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services